PAT Testing for businesses plays a vital role in keeping workplaces safe, compliant, and operational. Many organisations still treat it as a once-a-year chore. That approach misses the bigger picture. Portable Appliance Testing supports safety, protects equipment, and reduces disruption. For UK businesses that rely on technology every day, PAT Testing deserves proper attention.

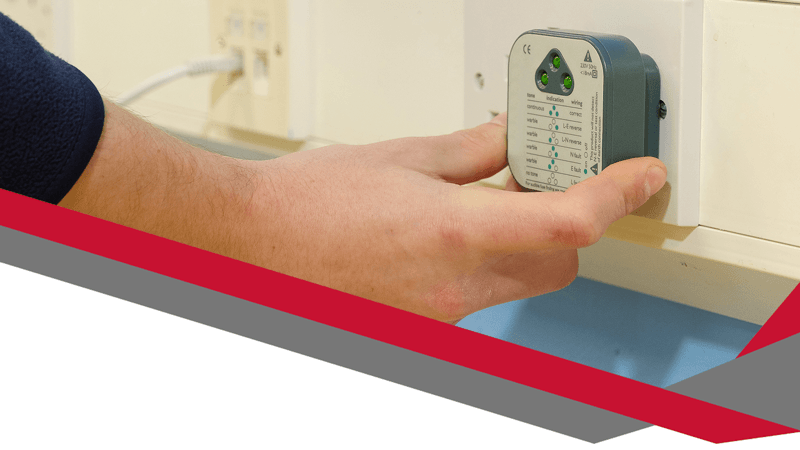

PAT Testing checks electrical appliances to confirm they remain safe to use. The process combines detailed visual inspections with electrical testing. Together, these steps identify wear, damage, and faults early. Early action prevents accidents, downtime, and avoidable costs. When equipment stays safe, teams stay productive.

Some numbers you might want to consider before we go further!

Data from the Electrical Safety First shows that electrical faults account for over half of all accidental fires in UK workplaces and commercial buildings.

ElectRIcal safety First

The same body highlights that portable appliances and extension leads are common sources of ignition when poorly maintained.

What counts as PAT Testing in a modern workplace

Portable appliances include any electrical item that plugs into a socket. Office environments rely heavily on such equipment. Computers, monitors, printers, desk lamps, chargers, and networking hardware all fall into scope. Each item carries potential risk if damaged or poorly maintained. PAT Testing assesses that risk in a practical way.

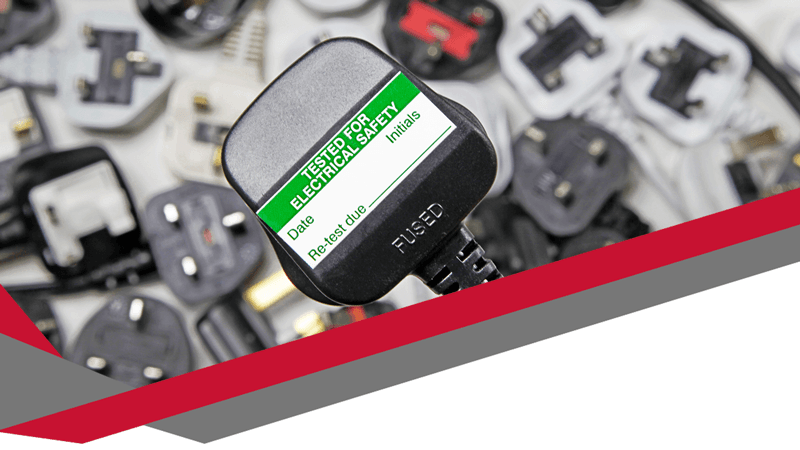

Testing focuses on three key areas. Visual checks spot obvious issues like frayed cables or cracked plugs. Electrical tests confirm correct wiring and insulation. Labelling then records the outcome clearly. This structured approach provides reassurance for employers and staff alike.

Why PAT Testing matters beyond compliance

Safety legislation in the UK requires employers to manage electrical risks. The Electricity at Work Regulations 1989 set clear expectations. Equipment must remain safe throughout its use. While the law does not demand PAT Testing by name, it expects reasonable steps. PAT Testing meets that expectation in a recognised and proportionate way.

Compliance alone should not drive action. Electrical faults cause fires, injuries, and lost working time. Even minor incidents disrupt operations. A failed power lead can halt a team for hours. Consistent testing reduces those risks significantly.

How PAT Testing supports business continuity

Technology underpins modern work. Phones, headsets, routers, and power supplies keep communication flowing. When equipment fails unexpectedly, customer service suffers. Deadlines slip. Reputation takes a hit.

PAT Testing helps prevent those scenarios. Regular checks identify deterioration before failure occurs. Planned maintenance always costs less than emergency fixes. Businesses that test proactively experience fewer surprises. That stability supports growth and confidence.

PAT Testing in offices, hybrid spaces, and home working

Work patterns have changed. Many teams now work across offices, shared spaces, and home environments. That shift complicates electrical safety management. Employers still hold responsibility for equipment they provide. Laptops, docking stations, and chargers travel between locations.

PAT Testing adapts well to these realities. Testing schedules can reflect usage and risk. High-use items receive more frequent checks. Low-risk equipment follows longer intervals. Flexibility ensures safety without unnecessary disruption.

How often PAT Testing should take place

No single timetable suits every business. Risk assessment drives frequency. Environment, equipment type, and usage all matter. For example, a busy office with frequent equipment movement faces higher risk than a static setup.

Many organisations adopt annual testing as a baseline. Others test certain items every two or four years. Visual checks often happen more frequently. Clear records support decisions and demonstrate due diligence.

Common misconceptions that cause problems

Some businesses assume new equipment does not need testing. That belief creates gaps. Manufacturing faults and transport damage still occur. Initial testing confirms safety from day one.

Others rely solely on stickers from previous years. Labels alone prove nothing without records. Documentation matters during inspections and insurance claims. Accurate logs protect businesses when questions arise.

What a professional PAT Testing service provides

A competent PAT Testing provider brings expertise and consistency. Trained testers understand regulations, equipment types, and testing methods. Professional services also minimise disruption. Testing often happens outside peak hours or in planned phases.

Reports form a crucial part of the service. Clear records list tested items, results, and recommended actions. Those documents support audits and internal reviews. Reliable providers also offer guidance on future testing cycles.

Linking PAT Testing with wider IT and telecoms support

Electrical safety does not exist in isolation. IT infrastructure depends on reliable power. Network outages often trace back to faulty equipment or overloaded extensions. PAT Testing reduces those risks.

For businesses using advanced communications, safety underpins performance. Headsets, handsets, and routers must remain reliable. Regular testing complements ongoing IT and telecoms maintenance. Together, these services create resilient systems.

Businesses exploring professional PAT Testing services alongside their wider technology support often benefit from joined-up thinking. Integrated approaches reduce gaps and simplify management. Digicomm 360 supports businesses with technology-led solutions that prioritise reliability and compliance through services such as professional PAT Testing.

External guidance and recognised standards

Authoritative guidance helps businesses understand best practice. The Health and Safety Executive provides clear advice on electrical safety and PAT Testing expectations. Their guidance explains legal duties and sensible precautions. You can review official information through the Health and Safety Executive’s electrical safety guidance.

Using trusted sources strengthens internal policies. It also reassures stakeholders that decisions align with national standards. Reliable information supports confident leadership.

Planning PAT Testing without disrupting work

Disruption remains a common concern. However, effective planning solves most issues. Asset lists help testers work efficiently. Clear communication prepares staff. Phased testing avoids unnecessary downtime.

Many providers now test quickly with minimal interruption. Portable equipment allows flexibility. Advance planning turns PAT Testing into a smooth process rather than a nuisance.

The long-term value of consistent testing

Over time, PAT Testing delivers more than safety. Data reveals patterns. Frequent failures highlight equipment quality issues. Replacements then become strategic rather than reactive.

Consistent testing also supports insurance compliance. Insurers expect evidence of risk management. Clear records reduce disputes after incidents. That protection alone often justifies the investment.

Final thoughts on PAT Testing for UK businesses

PAT Testing for businesses remains a practical, proven way to manage electrical risk. It protects people, equipment, and operations. When approached thoughtfully, testing supports productivity rather than interrupting it.

Businesses that integrate PAT Testing into their wider technology strategy gain clarity and control. Safety becomes part of everyday operations. Confidence grows. That foundation allows organisations to focus on what matters most.